We use the latest manufacturing techniques to ensure each bracket and guide meets dimensional and tolerance requirements exactly. Precise construction allows seamless integration into existing conveyor systems, reducing installation time and the need for fewer adjustments. This precision engineering means you are guaranteed optimal belt alignment to negate operational disruptions.

Our conveyor side brackets & guides can be adapted to manufacturing industries, food processing industries, pharmaceutical industries, and also logistics. Their powerful and versatile design makes them fit for application in various types of conveyors, including belt conveyors, roller conveyors, and modular conveyors. Furthermore, they can be set up for both straight and curved conveyor paths with unparalleled flexibility in application. Our products have durability as an important characteristic. The brackets and guides are designed to resist wear by friction, impact, and other environmental factors.

Features such as anti-rust coatings, strengthened edges, and quality finishes increase the life of these parts. This durability equates to cost savings for the client by reducing maintenance and replacement needs. Guides are made to allow smooth and continuous travel of materials on the conveyor. This helps minimize the potential for product damage, while operations become more efficient. The frictionless surface of guides diminishes frictional resistance so that items glide along easily, even at high speed. This is so important in industries dealing with delicate or fragile products.

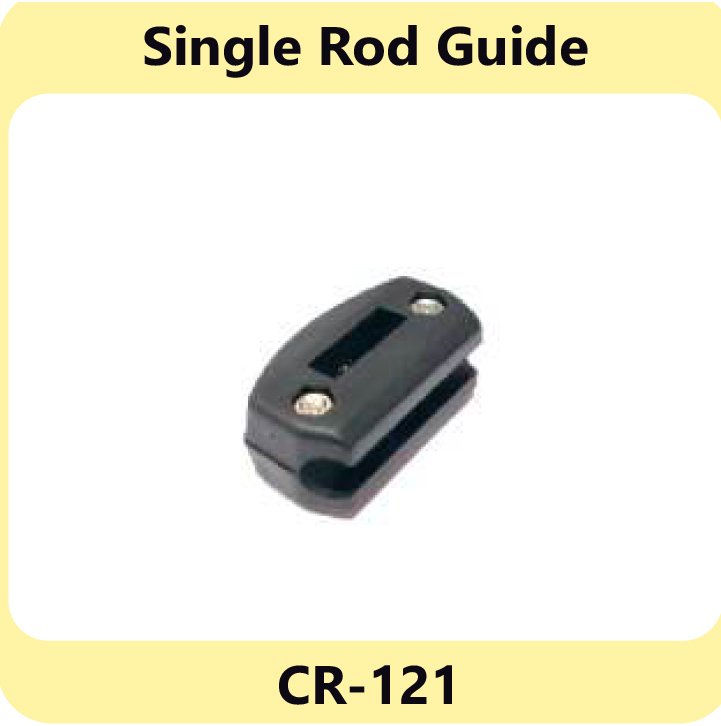

| Usage/Application | Conveyor Side Bracket & Guides |

| Material | Nylon |

| Structure | Belt Conveyor, Chain Conveyor |

| Color | Black |

| Brand | Flexline |

| Condition | New |

| Minimum Order Quantity | 1 Piece |