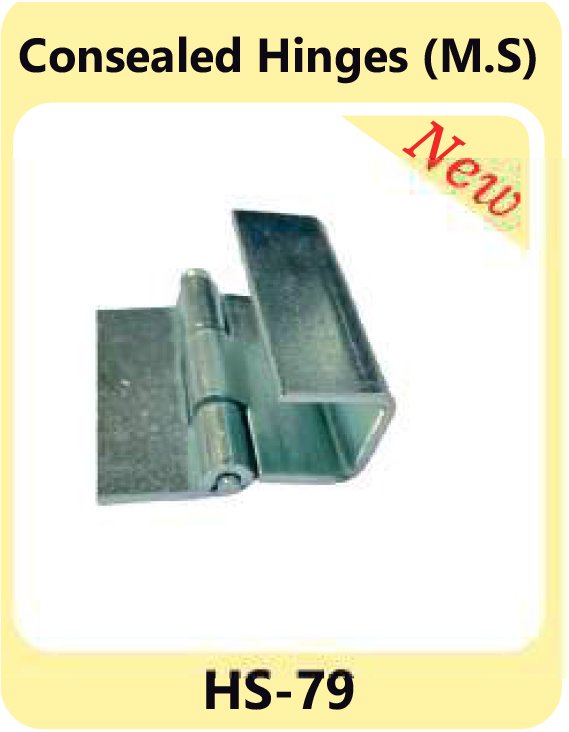

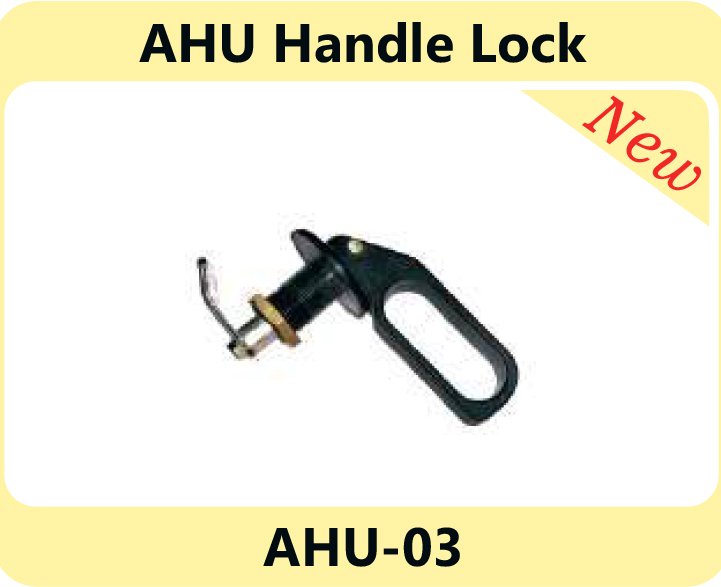

It should also minimize downtime, thus considering ease of installation and maintenance, allowing for easy access to internal components when servicing or repairs are required. Additionally, special custom-fabricated hinges can be fabricated according to unique AHU design needs with respect to both form and function. Rigorous testing ensures each hinge meets or exceeds industry standards for strength, longevity, and operational reliability to add to the overall efficiency and lifespan of the AHU. We give a comprehensive specification of the load-wear capacity, material composition, and finish options to facilitate customers in picking out the hinges most suited for their required applications.

The materials used in our hinges and accessories are selected to offer optimum performance and durability in what is sometimes a pretty hostile environment-in an AHU. With its renowned corrosion resistance and tensile strength, stainless steel is mainly used for items that undergo constant exposure to water and chemical conditions of changeable ambient temperatures. Lighter-duty applications utilize aluminum alloy material-much lighter, but strong and durable for the forces encountered by many end.

Finishes include powder coatings and specialized surface treatments for increased corrosion protection and aesthetic appeal. Protective coatings greatly increase the life of the hinges and accessories by resisting wear and tear while maintaining the structural integrity of the components. Material selection is based on operating conditions of the AHU, load capacity, and aesthetic results desired. This is a rigorous approach that guarantees our hinges and accessories will be durable and perfectly matched to the demands of the application.

| Usage/Application | Hinges & AHU Accessories |

| Material | Nylon |

| Structure | Belt Conveyor, Chain Conveyor |

| Color | Black |

| Brand | Flexline |

| Condition | New |

| Minimum Order Quantity | 1 Piece |